Producing dryer machines and developing machines which process carpets like fabric, Entema is ready for new projects! Sharing operations of the firm with us, Ömer Gökcan, Partner and Mechanical Engineer of Entema firm, has also announced they had new TUBITAK projects.

Producing dryer machines and developing machines which process carpets like fabric, Entema is ready for new projects! Sharing operations of the firm with us, Ömer Gökcan, Partner and Mechanical Engineer of Entema firm, has also announced they had new TUBITAK projects.

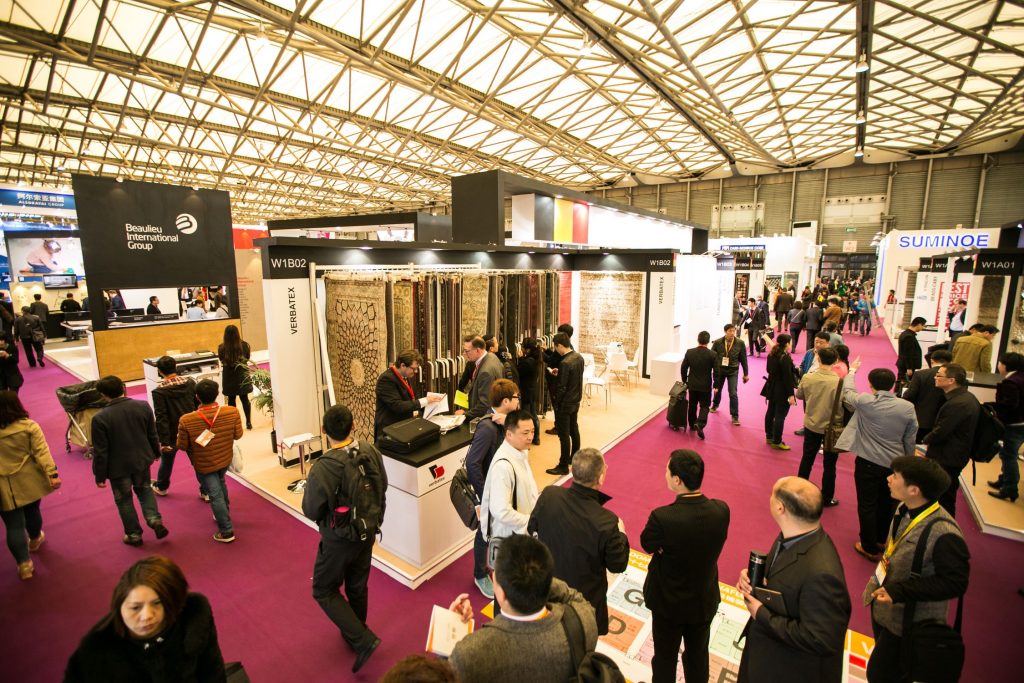

Entema firm laid its first foundations in 1992 in Çorlu/Tekirdağ. In the establishing period the firm set out to act as mechanical engineering and contracting services for the industrial facilities in the region. Then determining fabric drying processes as the main target in the textile sector, the firm has started machinery production in this area. Stating oriented on a single issue that had brought advantage and they had gotten returns of that, Ömer  Gökcan said Entema has gained deserved return with customer satisfaction which has been won in a short time through Entema relax fabric dryer machines in the domestic market.Entema represents the sector across the world Stating having improved continuously by R & D studies, as well as joining and promoting at the international fairs, Entema products have taken place among brands which are preferred in the other textile producer countries, Gökcan said, “We have been representing our country in the markets of South American, North African, Middle Eastern, Central Asian, Asia Pacific and the Far Eastern markets for years.”

Gökcan said Entema has gained deserved return with customer satisfaction which has been won in a short time through Entema relax fabric dryer machines in the domestic market.Entema represents the sector across the world Stating having improved continuously by R & D studies, as well as joining and promoting at the international fairs, Entema products have taken place among brands which are preferred in the other textile producer countries, Gökcan said, “We have been representing our country in the markets of South American, North African, Middle Eastern, Central Asian, Asia Pacific and the Far Eastern markets for years.”

Offered under the registered SWELLSOFT brand to the market with the international patented multi-purposed Open width Continue Tumbler Dryer Machines has been firstly entered into force benefiting from TUBITAK R & D supports for the fabric finishing such as towels, velvets. Repeated machinery orders in line with increased needs of current users both in the home and foreign markets, Entema products display its gained success across the world.

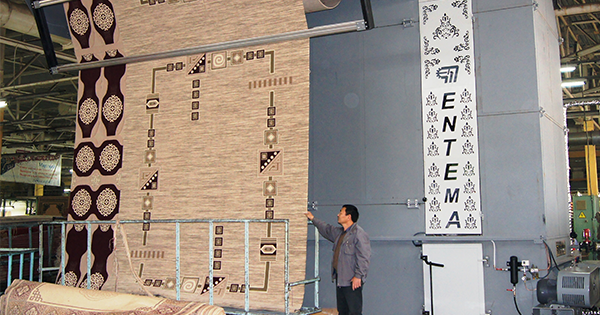

First carpet finishing machine of the world…

The first prototype model was displayed in 2011 at ITMA Textile Machinery Fair held in Barcelona/Spain. Stating they had improved the carpet version of the machine regarding the demand came from there, Gökcan said, “The first SWELL SOFT – Carpet Finishing Machine has been commissioned by one of the most important firms of Turkey at Sanat Halı Gaziantep factory. As for another machine, it entered into force at Erdenet Carpet firm in Mongolia.” Ömer Gökcan also added positive negotiations were continuing both in the home and abroad in the other carpet producer countries such as Belgium, Iran, Egypt, China.

In textile having used for long time through the main principle by letting fabrics such as velvet, upholstery, towel crash onto a special surface through being heated, steamed in a cabin condition, now thanks to SWELLSOFT – Carpet Finishing Machine’s patented methods and special construction these processes are applied in carpet processes.

![y]n](https://www.decor-mag.com/wp-content/uploads/2016/10/yn-300x231.png) On other words, now carpets can be processed like fabrics with SWELLSOFT. At the carpets which are produced by viscos, bamboo, wool, acrylic, polyester or mixtures of these materials, in addition extraordinary dust cleanness, also different effects and a soft touching can be obtained, also all tensions which stem from weaving processes. In addition, clear increases have been seen in friction durability of products through the tests made.

On other words, now carpets can be processed like fabrics with SWELLSOFT. At the carpets which are produced by viscos, bamboo, wool, acrylic, polyester or mixtures of these materials, in addition extraordinary dust cleanness, also different effects and a soft touching can be obtained, also all tensions which stem from weaving processes. In addition, clear increases have been seen in friction durability of products through the tests made.

SWELL SOFT Carpet Finishing Machine offers effective solutions

Having produced by the latest technology, SWELL SOFT Carpet Finishing Machine draws attention by offering advantage and solutions. The foremost features of the machine can be listed as follows;

Advancing continuously into cabin in relax way, as connecting heated and steamed circulation air (according to demand) simultaneously, a unique homogenous massage through both sides or wanted side let carpet piles activate, comb, swell, soften and fix. Different pile stance can be obtained by implementing this process both same or opposite side. The tensions which stem from weaving process can be removed, a very smooth three dimensional and flexible construction can be obtained.

- After weaving and before trimming, carpets, which were processed by SWELL SOFT, were purified from its dusts and lint and letting the piles upright to their real size, being brought upright position provides ideal condition for trimming process and increases trimming quality.

- The piles which make up visual problem during weaving and waiting period set them order in line with wrap and warp and getting fixed. With this effect designs reach permanently their real and net view. With effect of heat and steam, refreshment is obtained in colors.

- It is possible to process the laminated products only at side of piles without damaging lamination.

- Regarding jut and fiber dusts on back of carpets can be cleaned with double sided special massage, dust contamination problem on front surface of rolled carpets are fully removed.

- Thanks to Swell Soft patented methods, the products ranging from input and output of the machine the problems such as abraj, weight loss, wrinkling are not experienced due to any rubbing does not happen. If there are, these kinds of problems stem from previous processes can be removed.

International standards are taken base in production

The machines are designed taking into consideration of all measurements regarding deteriorating environmental conditions of the world. Ömer Gökcan stated the machines produced in the international standards having CE certificate.

If stated by the numbers, a SWELL SOFT is used in finishing of a carpet in 5 m. width, weighting 5 kg/m2 – while Carpet Finishing Machine operates in regime condition;

- Practical electricity consuming is nearly in 30kW/H level.

- Together with showing variation noise decibel is under generally 90 decibel.

- The machine continuously cleaning itself in operation mode, exhaust gas is sent outside by being filtered.

- Taking into consideration 24/7 working conditions and designed PLC controlled the machine’s maintenance need and operation is easy.

- Having designed as vertical the machine covering space in the factory is quite few. For example, 5m.x8m. setting space is enough for a Swell Soft which processes a carpet in 5 m. width.

A new TUBITAK project is coming

Seamless innovation is the principle of the firm, feedbacks of customers about products are considered and these criterions are taken into consideration continuously in product improvement.

On the other hand stating their R & D studies are continuing nonstop Gökcan concluded they had been in preparation to a project supported by TUBITAK for a new version of this product in the period of 2016-2017 along with a foremost textile establishment of the country.