SWELL SOFT Carpet finishing machine, which is a result of the combination of R&D works, experience and fund of knowledge for 20 years within ENTEMA and is the company’s patented product that has been worked on since 2008 attracts the manufacturers in domestic and foreign markets.

SWELL SOFT Carpet finishing machine, which is a result of the combination of R&D works, experience and fund of knowledge for 20 years within ENTEMA and is the company’s patented product that has been worked on since 2008 attracts the manufacturers in domestic and foreign markets.

“First prototype of Swell Soft open width continuous tumbler machine, actualized by the supports of R&D of TUBITAK to finish towels and velvet like fabrics, was introduced to the World markets in ITMA Textile Machine Fair organized in Barcelona / Spain in 2011. After this introduction the carpet type of the machine was developed and the first carpet finishing machine was introduced to the use of one of the leader brands in Turkey, SANAT HALI, in June 2012. For more than one year, system performance has been analyzed on viscose and acrylic carpets, and after the successful results we have focused on the wool carpets.” the executive of the company, Ömer Gökcan said. “The machines bought in October, 2013 have been integrated in the wool carpet process of ERDENET CARPET which has more than 30-year experience in this sector and has been producing 100% wool carpets with Woolmark License in its integrated plant with 1500 personnel in Mongolia.” he added.

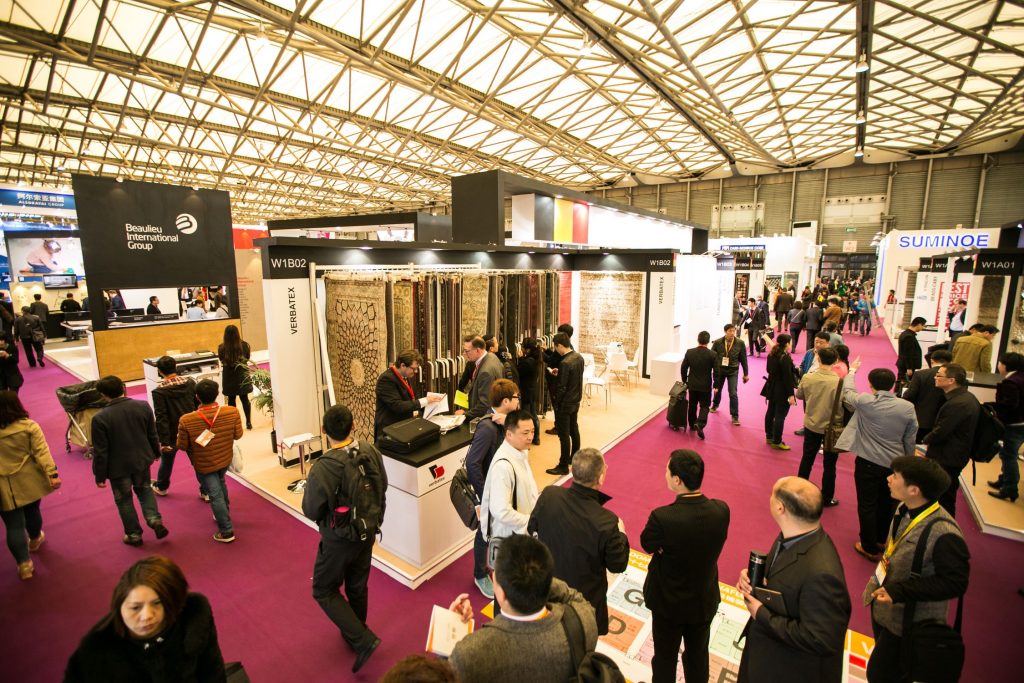

“SWELL SOFT TREATS THE CARPET LIKE FABRIC” “’Continuous tumbler process’ has been used in textile sector for the finishing of velvet, upholstery fabric, towel, etc. Main principle of this process is to hit the fabric to the special surfaces due to mechanical forces in a heated and vaporous booth and to make it softer and more firm. Thanks to patented methods and special construction of SWELL SOFT carpet finishing machine, now this process may be applied to the carpet finishing.” the executive of company Ömer Gökcan said. “This process achieves different visual and touching effect in addition to the extraordinary dust cleaning in the carpets made of viscose, acrylic, polyester, wool and the mixture of these materials. Relaxed effect in the piles and general texture removes the tension which is a result of weaving process.” he added. He also gives the following information:Our machine has a heating system, high efficiency and low energy radial circulation fans, exhaust fans, filters and automatic dust discharge system. • Circulation air is prepared by heating it under the control of a processor and in the required process temperature by one of the vapour, boiling oil and natural gas heating Systems. • To obtain different effects, the vapour in requested quantity may be mixed with the heated circulation air in the air preparation unit. • Conditioned air is blown from top to down thanks to circulation fans through air channels and special nozzles. • Used air passes through special filters and is absorbed and the collected waste air and dust are discharged from the booth thanks to automatic dust discharge system. • In the same way, exhaust air is absorbed through special filters and discharged after it is cleaned. • Cleaned and heated air again enters in to the air circulation. • Our machine has a no-dust collective design and it will clean itself during work. It is easy and takes a short time to clean the machine which can be reached from everywhere. • It is so easy to use the machine via PLC touch-screen control. Special designed, patented drums are situated in effect booth. Rotation ways and speeds of the drums may be electronically adjusted according to the carpet type processed. • While the unique (patented) homogen massage is applied from one or both side to the carpet which countinously and tension-freely flows and the heated and vapoured (if requires) air is circulated in the booth comb, lift, form and soften the piles of the carpet. This process is applied on the same and reverse way of the piles and different pile fittings may be achieved. Tension which is a result of weaving process is removed. A more straight 3-D construction is obtained and the 3-D flexibility and friction resistance of the carpet is increased. • After the weaving and before the trimming, cleaning of dust from the carpets processed in our machine and raising the piles to the real length and straighting the carpets provide the optimum conditions for trimming and increase the quality of trimming process and reduces the cutting faults. • Because of their flatness, the piles which intermingle and create visual problems are always and permanently adjusted through warp and weft way. This effect permanently creates true and clear appearance. Vivid colors are achieved.• It is possible to treat only from the pile side without damaging lamination in the laminated products. • Because the jute and fiber dust on the back of the carpet are removed thanks to double sided massage, front side dusting problem is solved even after the carpet is rolled or opened. • Thanks to the patented methods of Swell Soft, there is no risk for the products treated in a continuous and open width form such as crushing each other from the entrance of the machine to the exit. And weight loss and wrinkle problems which are result of the previous processes may be removed. • Energy consumption of our machine is in the minimum level. For example, while even treating a heavy carpet with 5mt. width and 4…5kg/m2, it consumes about 30kw/h electric energy. • Noise level of our machine changes according to the treated product type and it is generally low. • Vertically designed machines take so small place in the company. For example, 5mt.x8mt. settlement place is enough for a Swell Soft which treats 5mt. carpet • Maintenance need of our machines which is designed by considering 7day – 24 hour working conditions is minimized. “Mongolian wool is admired due to its strong nature; however it is also hard and highly dusty because of the harsh climate conditions. The problem with which ERDENT CARPET has encountered for 30 years due to the negative effect on the products is solved. After the conducted tests, more soft and bulky texture, clear patterns, vivid colors and non-dusty form has achieved in the quality of the carpet.” Ömer Gökcan said. “Thanks to the added values such as extra cleanness, durability, increased visuality and touching which are brought into the SWELL SOFT Carpet Finishing machine, we expect an increase in the sales of the next term.” he said in DOMOTEX 2014 / GERMANY fair. “We expect that SWELL SOFT Carpet Finishing machine which has come up with ideal solutions so far and has caused a stir in the World carpet industry will be an essential part of the carpet finishing processes in the following courses” he finished his speech.