Mennan Makina, which was deemed worthy of the Technology Achievement Award with the carpet yarn machine it produced in 1996, aims to carry its success even higher with the new projects it will carry out in 2022.

After founding his own company in 1973, Mennan Aksoy, who sought to do more qualified work, got the fruit of these efforts with the carpet yarn machine, which was built for the first time in Turkey. The master Mennan, who was able to manufacture this machine, which can be produced in a limited number of countries such as Germany, Italy and France as a result of intensive labor and research, crowned this work with the Technology Achievement Award in 1998. Ali Aksoy, General Manager of Mennan Makine, with whom we talked about the R&D studies they implement in the machines they produce and the automation systems, gave information about the special systems they use in their machines.

First of all, can you give information about your new production facilities?

We started production in our new facility with a total area of 10,000 square meters, of which 5 thousand square meters is closed, in the 2nd OIZ. Together with this production facility, we can produce 10 spinning machines per year. We have 50 personnel working continuously in our facility. With the periodic support we receive from outside, this number reaches 120 people in total. In addition to our own machinery, we produce our products in 3 different production facilities in Gaziantep and other provinces.

How did the founding story of Mennan Makina begin? What are your fields of activity?

Our brand started to produce with Gaziantep’s first TÜBİTAK project, Mennan Aksoy prepared in cooperation with Gaziantep University in 1996. Mennan Aksoy, who produced this carpet yarn machine in Gaziantep, which can be produced in a limited number of countries such as Germany, Italy and France, successfully completed this project and was awarded the Technology Achievement Award in 1998. After the successful conclusion of the first project, the brand focused on R&D studies in the following years, successfully completing 8 TÜBİTAK projects and breaking new ground in Synthetic Fiber and Yarn production in Turkey. Mennan Makine, which sells the machines it produces to countries such as Brazil, Egypt, Syria, Morocco, Saudi Arabia, Turkmenistan, Algeria, Uzbekistan and Iran, in addition to the domestic market, has made a significant foreign exchange contribution to our country. Our company, which has been producing synthetic yarn machines with the support of the university since 2013, is continuing to work on the design of systems that are more advanced than its European counterparts.

How do you serve the carpet industry? What are the conveniences you provide to your customers in your business relations?

The existence of textile is as old as human history. Natural fibers have been able to meet the needs of people for a long time. With the increase in the world population, that the natural fibers failed to meet the needs and that the textile sector spread to the carpet, curtain, car seat and similar sectors as well as the clothing industry have led to the birth of synthetic fibers. Synthetic yarn machinery production is carried out only by Mennan Makina in our country as well as in countries such as Germany, France, England and Italy in the world. The machines we produce show up not only in the domestic market but also in the world market. Our company provides the highest level of customer satisfaction by meeting customer needs in the most economical way and in the shortest time in line with the demands. Our company, which has CF, CF-HT, BCF, POY, FDY and Staple Fiber type spinning machines in its product portfolio, is taking firm steps towards the future with applications in accordance with total quality management, giving importance to R&D studies. BCF yarn is called carpet yarn and is used in tufted carpets. It is preferred due to its processing speed, ease of use, antibacterial and antistatic properties.

What are the differences in the automation systems of Mennan Makina? What are the points and advantages that distinguish it from other machines in its field?

We use Siemens brand controllers, drivers and switchgear in our machines. Siemens motion control products are used at the heart of the system. Simotion not only controls the motor, but also performs the precise temperature controls required by the machine with its technological temperature control. We also use Siemens’ state-of-the-art product Active Line system. In this way, we can minimize the system’s being affected by fluctuations that may occur in the network, and we reduce the energy consumption of the system by feeding the excess energy generated in the braking situation back to the grid.

Which countries do you work with on the export side? Is there a target market that you have determined by saying that we should be here too?

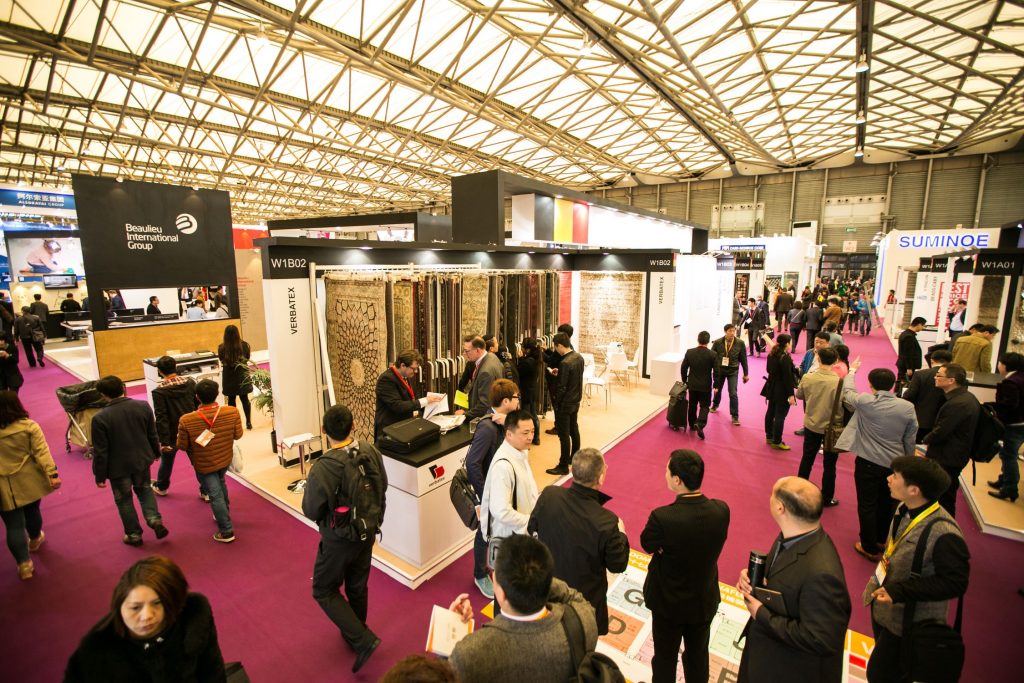

We generally work with Middle Eastern countries. Iran, Saudi Arabia, Egypt, Uzbekistan, Turkmenistan, Algeria, Morocco, Brazil, China and Syria are the leading ones. We also maintain contacts with countries such as India, Pakistan, and the United States.

When we compare the machinery industry in Turkey with the world, what kind of picture emerges? How have recent events affected the industry?

The Turkish machinery industry has been the rising star of the Turkish economy and exports in recent years. In the last 5 years, among the sectors that have a say in Turkey’s exports, the machinery sector has realized the highest increase with 67%. Turkish Machinery exports ranked 3rd in the world in terms of export growth with an average of 15% increase in exports in the last 5 years. The leading export markets of this sector are EU Countries and USA. In the Turkish industry, where total exports decreased by 2.7 percent in the January-September period compared to the same period of the previous year, exports of the machinery sector continued to increase. The machinery industry, which realized an export of 9.9 billion dollars in the first 9 months of the year, increased its exports by 1.8 percent compared to the same period last year and increased its share in Turkey’s total exports to 10 percent. All these factors, of course, have affected the textile machinery sector as well as every sector. The years 2020 and 2021 were good for Mennan Makina and we worked at full capacity. We have already filled our capacity for 2022.

What are your predictions for the year 2022, both as a sector and as Mennan Makine? Are there any new projects in 2022?

In the last 3 years, there has been a movement especially in the sector. As Mennan Makina, we have now completed the year 2022. There are also new projects that we are discussing. We think that we will complete the first half of 2023 within the next 1-2 months.